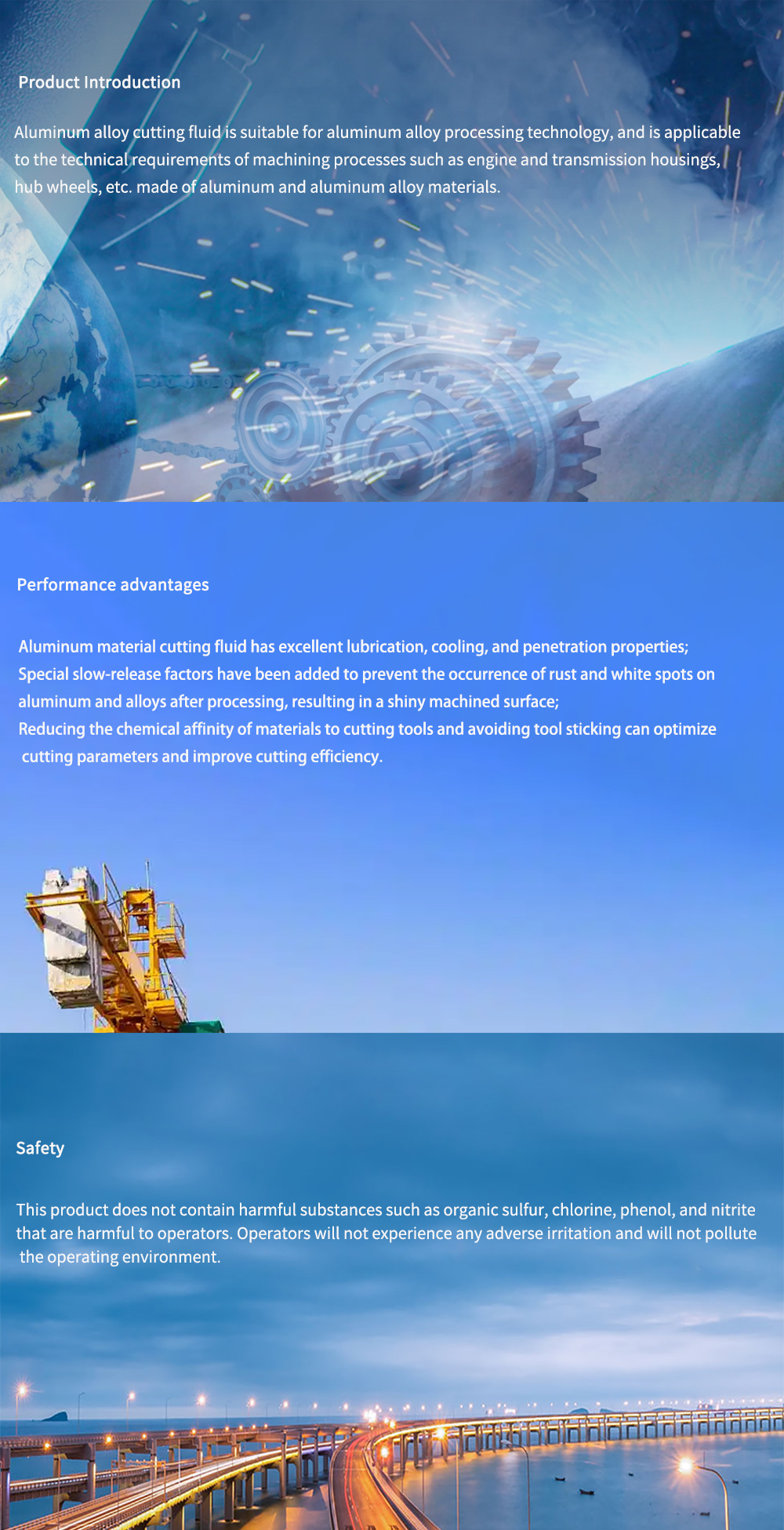

Aluminum alloy cutting fluid

It is suitable for the cutting process of non-ferrous metals with soft

hiddenValue

Details Introduction

[Interpretation of performance advantages of synthetic fat type synthetic cutting fluid]]

n rapeseed oil as base oil

Using rapeseed oil as base oil, through complex different process reactions to generate unique extrusion agent, anti-wear agent, corrosion inhibitor and lubricant, these unique basic formulations make the cutting fluid show excellent lubricity, cleaning, anti-wear, anti-extrusion, strong load capacity and antibacterial environment.

n long life, tasteless

This product has excellent lubricity, cooling, rust prevention, cleaning agent, sterilization and bacteriostasis, floating oil and settling iron filings, which achieves the advantages of continuous use of its working fluid for 1-2 years and constant quality of working fluid in the processing process, reduces the consumption cost of the enterprise, improves the production efficiency, relieves the problems of waste water treatment, waste liquid discharge and environmental protection in machining enterprises, and reduces the labor intensity of operators, it enables enterprises to significantly reduce the cost of use and emissions.

n Low emission, maintenance free

The cutting fluid synthesized with edible rapeseed oil as base oil has less pollution, degradability and low waste liquid treatment cost. Because the product itself has excellent floating oil, settling iron filings and bactericidal and antibacterial properties, its working fluid realizes self-regeneration and maintenance-free functions, regardless of its concentration, and its working fluid has stable PH value. It only needs to be added when used, and it is discharged once every 1-2 years, and it is easy to discharge.

n lubricity

Under the condition of light-load cutting, the oiliness agent of this product is easy to form a physical adsorption film on the cutting interface. The physical adsorption film plays a role in reducing friction and can improve the lubricating performance of cutting fluid. Under the condition of heavy-load cutting, the lubricant and the extrusion antiwear agent synergistically enhance its abrasion resistance and extrusion performance, and form a high-strength chemical reaction film on the cutting interface, which will not be damaged under the action of high temperature, high pressure and intense friction, play a good extreme pressure lubrication, the lubrication at this time is in the boundary lubrication state, reduce the friction between the rake face and the chip, the flank face and the surface of the workpiece, prevent the adhesion between the tool and the chip, the tool and the workpiece, and reduce the cutting heat, power consumption and tool wear, solve the problem that ordinary cutting fluid cannot really cool and lubricate the tool, and improve the service life of the tool, the tool improves the finish of the workpiece being processed.

n rust resistance

Multi-functional anti-rust, anti-corrosion additives and corrosion inhibitors are added to make the cutting fluid products meet the requirements of anti-rust and anti-corrosion. In the coastal and southern humid areas, the cutting fluid processing of the workpiece between the process of rust-proof up to 8-15 days, no need to apply anti-rust oil.

n cleaning

The scientific ratio and advanced production technology provide excellent anti-fatigue, high temperature stability and cleaning performance for this product, and solve the problems of skinning, caking, blocking the processing liquid delivery pipe and blocking the filter before the production workshop.

n bactericidal bacteriostasis

The added bactericidal compound and unique basic preparation make the product kill and inhibit bacteria and mold efficiently and durably at the same time. No additional bactericide is required during use, but the working liquid with the original ratio concentration (generally 5-10%) is added according to consumption.

n Floating dirt and iron filings

It has excellent effects of floating oil and sinking iron filings (powder), making the working fluid float to the liquid level during continuous use, and iron filings (powder) and sludge sink to the bottom of the water tank. As long as the oil spill and chip removal facilities are in place and maintained in place, and the working fluid has self-regeneration function, the circulating working fluid is clean and clear, and does not affect the observation of workpiece smoothness during processing, the dirt and hard particles in the cutting fluid are avoided to contaminate and scratch the surface of the workpiece again.

n security

This product does not contain organic sulfur, chlorine, phenol and nitrite and other harmful substances to the operator, the operator will not appear any adverse stimulation, also does not pollute the operating environment.

| Product Model | Performance advantages | Scope of application | proportioning concentration |

| KRB-CL106 |

Aluminum material cutting fluid, lubrication, cooling, excellent permeability; The special slow-release factor is added to avoid the corrosion of black and white spots after aluminum and alloy processing, and the processing surface is bright; Reduce the chemical affinity of the material to the tool, avoid sticking to the knife, optimize the cutting parameters and improve the cutting efficiency. |

It is suitable for the cutting process of non-ferrous metals with soft and viscous materials such as aluminum and aluminum alloy, as well as cast iron and stainless steel. |

5%--10% |

| KRB-ES406 |

Cleaning, excellent cooling, non-stick knife processing; The unique slow release factor is added, which has excellent anti-corrosion protection for aluminum alloy and can effectively prevent the surface of parts from blackening and oxidation. |

Suitable for aluminum alloy processing technology, suitable for aluminum and aluminum alloy material engine and gearbox housing, wheel hub and other machining process technical requirements. | 5%--10% |

Key words:

Industrial cleaning agent

Product inquiry

Note: Please leave your phone number or E-mail and our professionals will contact you as soon as possible!

Related Products