KRB-8507 multifunctional silane treatment agent

hiddenValue

Details Introduction

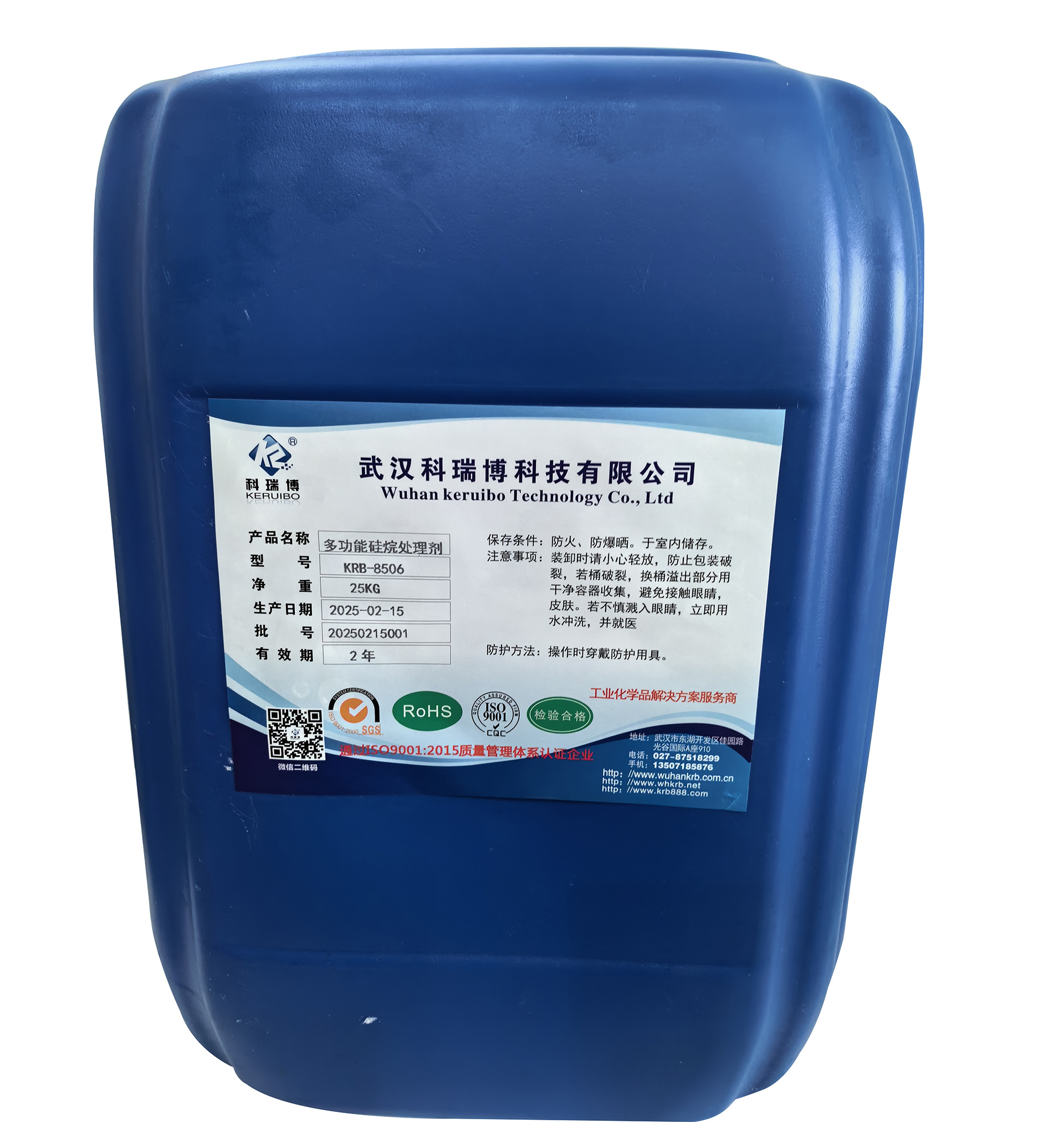

KRB-8507 Multifunctional Silane Treatment Agent

I. Product Introduction

KRB-8507 is a new type of environmentally friendly, multi-functional, composite silane pretreatment agent for spraying. It can simultaneously achieve multiple functions such as oil removal, film formation, and rust prevention, and does not require water washing, truly achieving zero wastewater discharge. It provides a perfect process solution for various shorter metal product coating production lines or factories that do not have pretreatment production lines due to substandard environmental impact assessments. After using this product, the workpiece needs to be dried, and then powder or paint is sprayed. This product has strong penetration ability. For slightly oily workpieces, this product can penetrate the oil film and reach the substrate, undergo polycondensation reaction with the substrate and form a covalent hydrogen bond, and then crosslink with the coating, thereby providing excellent coating adhesion and salt spray resistance.

II. Product Features

Simple operation: only one tank! One product! One process! Tank solution control is extremely simple, easy to learn, and can achieve fool-proof operation.

Simple operation: only one tank! One product! One process! Tank solution control is extremely simple, easy to learn, and can achieve fool-proof operation.

Wide applicability: applicable to all metal materials, including stainless steel, copper, titanium alloys, etc.

Wide applicability: applicable to all metal materials, including stainless steel, copper, titanium alloys, etc.

Safe and environmentally friendly: This product does not contain phosphorus, heavy metals, aromatic hydrocarbons, and other harmful substances; it is absolutely safe and environmentally friendly.

Safe and environmentally friendly: This product does not contain phosphorus, heavy metals, aromatic hydrocarbons, and other harmful substances; it is absolutely safe and environmentally friendly.

Energy saving and emission reduction: room temperature treatment, zero wastewater discharge.

Energy saving and emission reduction: room temperature treatment, zero wastewater discharge.

III. Usage Process

Suitable for various processing methods such as immersion, spraying, ultrasonic, and manual scrubbing

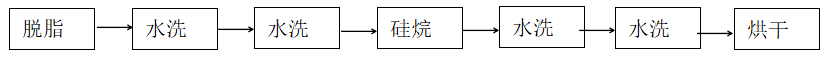

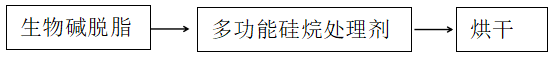

Traditional silane process:

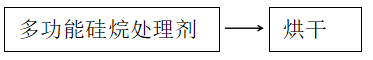

Multifunctional silane process:

For substrates with light oil stains

For substrates with heavy oil stains

IV. Usage Method

Construction method: Spray directly onto the surface of the workpiece. A processing time of 3 minutes or more is recommended.

Usage temperature: Room temperature ~ 40℃

Usage concentration: The recommended usage ratio is 3~5%. Our sales representatives will tailor the appropriate usage ratio to your specific on-site conditions.

Usage time: 1~10 minutes, adjust according to the workpiece surface condition.

After using this product, the workpiece is slightly leveled, then dried at above 100℃, and then painting or powder coating can be performed.

Note: This product does not have a rust removal function. For workpieces with rust, rust removal is required in advance.

V. Testing and Analysis

Tank solution pretreatment (This step can be ignored for newly prepared tank solution; only for old tank solution that has been used for a period of time):

Take 200ml of silicon crystal tank solution, add 2ml of silicon crystal reagent #1, and stir well; then add 1ml of silicon crystal reagent #2, and stir well again.

After the tank solution is allowed to stand and separate, the upper clear liquid can be used for the next detection step.

Chemical titration method:

Use a pipette to transfer 10ml of clear silicon crystal tank solution to a 100ml Erlenmeyer flask, add 5-8 drops of methyl orange indicator, and titrate with silicon crystal titrant #3. The endpoint color changes from yellow to red. The amount of silicon crystal titrant #3 consumed at this time is the concentration of the silicon crystal.

The silicon crystal concentration detected using the chemical titration method should be controlled within the range of 2.1~2.5.

Instrument detection method:

Testing instrument: HT-350

Testing method: Take a small amount of clean B-8507 tank solution, use a pipette to drop it into the sampling bottle, fill the sampling bottle and close the lid, insert the sampling bottle into the HT-

350 instrument test chamber, press the instrument OK button to read the value, the screen displays measuring, and the value can be read in a few seconds.

The silicon crystal concentration detected using the instrument detection method should be controlled within the range of 80~120.

VI. Packaging and Storage

25kg/barrel, 200kg/barrel, 1000kg/barrel

25kg/barrel, 200kg/barrel, 1000kg/barrel

This product should be stored in a ventilated and cool place, away from high temperatures, and avoid placing it together with acidic substances

This product should be stored in a ventilated and cool place, away from high temperatures, and avoid placing it together with acidic substances

Key words:

Industrial cleaning agent

Product inquiry

Note: Please leave your phone number or E-mail and our professionals will contact you as soon as possible!

Related Products