KRB-708 stainless steel paint remover

This product is mainly suitable for stainless steel or other alloy paint thick workpiece

hiddenValue

Details Introduction

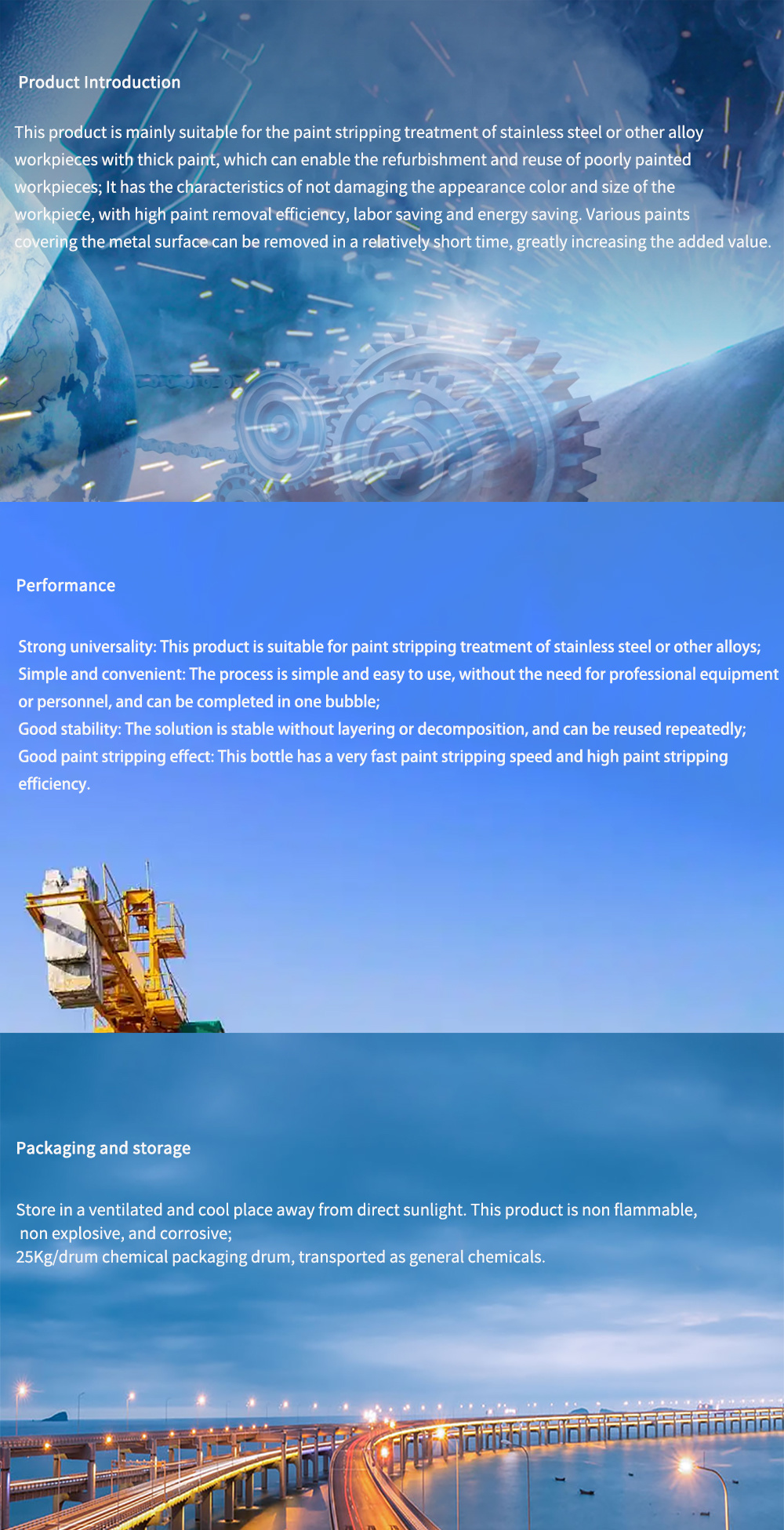

Introduction

This product is mainly suitable for stainless steel or other alloy paint thick workpiece paint stripping treatment, can make the poor painting workpiece again renovation and utilization; It has the characteristics of not destroying the appearance, color and size of the workpiece, high paint stripping efficiency, labor saving and energy saving, and can strip off all kinds of paint covered on the metal surface in a short time, thus greatly increasing the added value.

characteristics and advantages

l Versatility: This product is suitable for stainless steel or other alloy paint removal treatment;

l Simple and convenient: the process is simple and easy to use, without professional equipment and personnel, a bubble;

l Good stability: the solution is stable, not stratified, not decomposed, can be used repeatedly;

L paint removal effect is good: this product is very fast, paint removal efficiency is high.

physicochemical properties

|

KRB-708Stainless steel paint remover |

Typical data |

Test Standard |

|

relative density |

1.30±0.05 |

gravity meter |

|

Appearance |

Colorless transparent liquid |

Visual |

|

PHValue |

2-3 |

PHTest paper or digital display tester |

|

water soluble |

Insoluble in water |

Visual |

Method of use

1. For the first time to use this product, please read the instructions carefully. For those who have no experience, use it under the guidance of technical personnel. It is recommended to sample first and then batch produce it.

2. This product is used at room temperature, if used in cold areas, the temperature should be kept within 15-40 ℃.

3. Place the workpiece to be stripped in this product and soak it for 5-10 minutes. Visual inspection of the stripping condition can extend the soaking time appropriately. After the treatment is completed, take it out and rinse it with clean water to start the next process.

Process flow

Paint removal → water bleaching → oil removal → water bleaching → next process

The above process can be increased or decreased according to the actual situation

Product replacement cycle

Our research has proved that when this product is poured into a container, it just submerges the workpiece to be stripped, and about 5-7 batches can be stripped after repeated cycles.

Precautions

This product is an acidic product, please distinguish when using it to prevent the solution from being invalid due to the string tank;

This product can be processed at room temperature, heating is not recommended. The paint stripping time depends on the effect, and the paint stripping time of some paint films will be prolonged.

This product in the use of the process should avoid contact with the skin and eyes, such as contact with a large number of water rinse in a timely manner

Common Problem Solving

1. This product is volatile and has a pungent smell. When used, a small amount of water will be suspended on the surface and sealed. It should be covered when not in use.

2. After use, the liquid should not be poured back into the barrel to avoid reaction with the new liquid and failure.

Wastewater treatment shall be discharged according to the requirements of environmental protection regulations.

Storage and packaging

Avoid exposure to the sun placed in a ventilated and cool place to save, this product does not burn, do not explode, corrosive;

25Kg/barrel chemical packaging barrel, according to the general chemical transportation.

Key words:

Industrial cleaning agent

Product inquiry

Note: Please leave your phone number or E-mail and our professionals will contact you as soon as possible!

Related Products