KRB-15 passivator

KRB-15 is aluminum, aluminum alloy, zinc, zinc alloy and other special surface passivation agent.

hiddenValue

Details Introduction

1. scope of application:

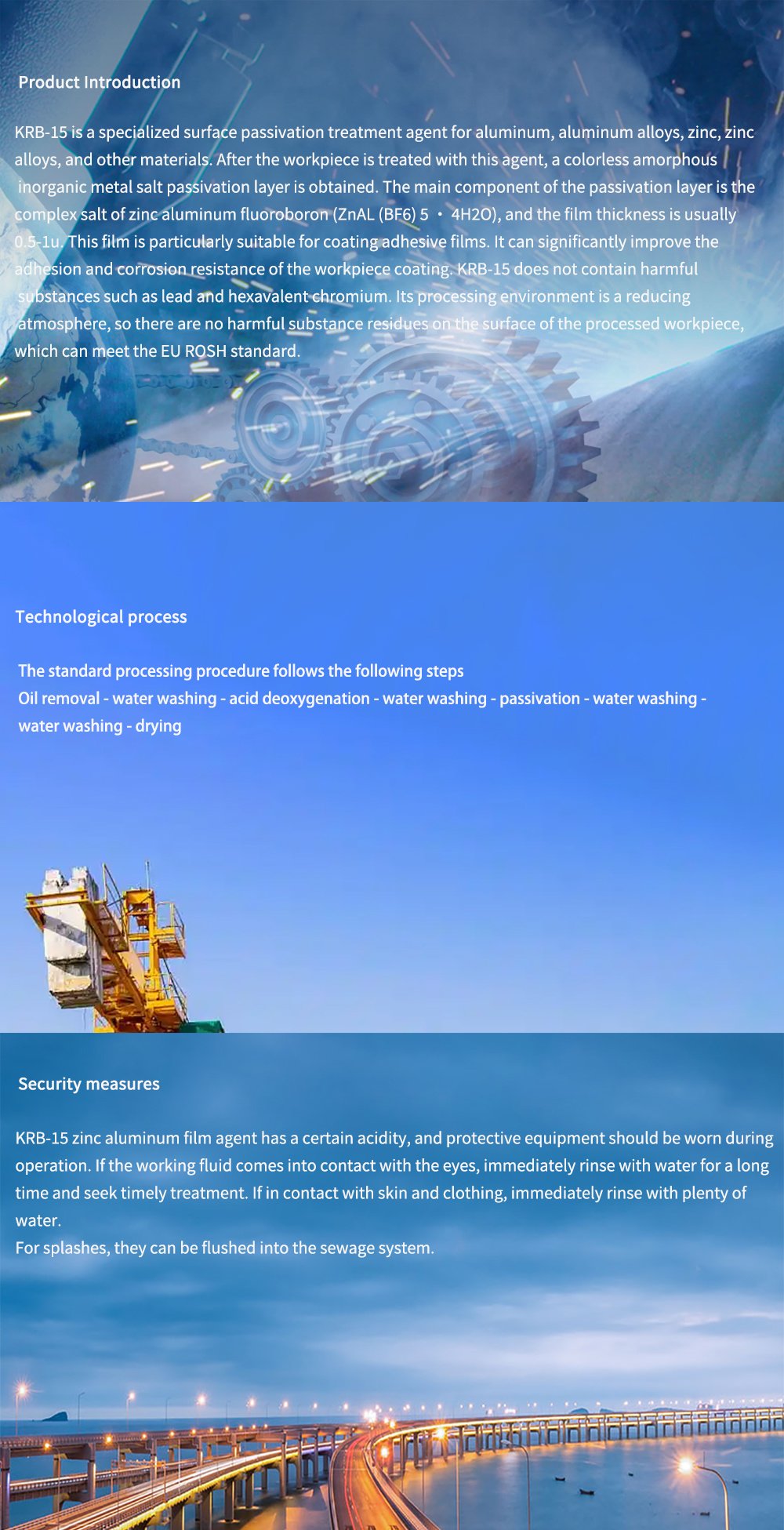

KRB-15 is aluminum, aluminum alloy, zinc, zinc alloy and other special surface passivation agent. The workpiece is treated with this agent to obtain a colorless amorphous inorganic metal salt passivation layer, the main component of the passivation layer is zinc aluminum fluoride boron double salt (ZnAL(BF6)5-4H2O), the film thickness is usually 0.5-1u. This film is particularly suitable for coating with films. Can significantly improve the adhesion and corrosion resistance of the workpiece coating. The KRB-15 does not contain harmful substances such as lead and hexavalent chromium, and its processing environment is a reducing atmosphere, so there is no harmful substance residue on the surface of the processed workpiece, which can reach the EU ROSH standard.

2. Appearance:

KRB-15 coating agent is yellow-green transparent liquid.

3. test reagents:

0.1NNaOH, phenolphthalein indicator

4. process:

The standard processing procedure follows the following steps

Degreasing-water washing-acid deoxidation-water washing-suicidalization-water washing-water washing-drying

5. KRB-15 zinc-aluminum coating agent bath (1000L)

1. Add clean water to 80% of the treatment tank

2. Add 100kg KRB-15 coating agent and fully stir

3. Add clean water to the scale of 1000L, fully stir evenly

The above bath concentration and treatment conditions are normal treatment conditions.

7. process control:

Total Acid Test:

Take 10ml of working solution, add 2-3 drops of phenolphthalein indicator, and titrate with 0.1NNaOH reagent until the solution changes from colorless to pink as the end point. At this time, the ml number of 0.1NNaOH reagent consumed is the total acid point.

Total acid control range: 20-55 points

The international general salt spray test method is used for the detection of the skin film.

Usually salt spray test ≥ 100 hours

8. safety measures:

KRB-15 zinc aluminum coating agent has a certain acidity, the operation should wear good protective equipment, such as working fluid contact with the eyes, immediately rinse with water for a long time, and timely treatment. If contact with skin and clothing, rinse immediately with plenty of water.

For spills, they can be flushed into the sewage system.

Key words:

Industrial cleaning agent

Product inquiry

Note: Please leave your phone number or E-mail and our professionals will contact you as soon as possible!

Related Products